Weidmuller Terminal Blocks

Weidmuller terminal blocks are used primarily for industrial applications where numerous electrical wiring ends must be connected together. This can be where a multi-conductor cable is connected to individual devices in a junction box. Or, many terminal blocks can be placed into a marshalling cabinet to better organize or de-scramble field wiring prior to connection to a PLC or Process Control System.

Weidmuller terminal blocks make efficient usage of available space. The W-Series WDU 2.5 and the Z-Series ZDU 2.5 are only 5 mm thick! You can install 60 of these terminal blocks in only one foot of DIN rail mounting space!

Weidmuller manufactures and distributes numerous types of terminal blocks for a wide variety of applications. All of the types described below are modular. This means that a variable number of terminal blocks can be assembled together to meet the specific project requirements. The terminal blocks are affixed to DIN rail and held in place with clamps at each end. The terminal blocks are usually marked with tags in a numeric sequence. |

|

|

Some of these types of Weidmuller modular terminal blocks are:

- W-Series Screw-Clamp Terminal Blocks

- Single Level Feed-Through Terminal Blocks

- Multi-Level Terminal Blocks

- Disconnect Terminal Blocks

- Fused Terminal Blocks for Circuit Protection

- Ground Terminal Blocks

- Z-Series Tension Clamp Terminal Blocks

- Single Level Feed-Through Terminal Blocks

- Multi-Level Terminal Blocks

- Disconnect Terminal Blocks

- Fused Terminal Blocks for Circuit Protection

- Ground Terminal Blocks

- SAK Series Screw-Clamp Terminal Blocks

- Single Level Feed-Through Terminal Blocks

- Multi-Level Terminal Blocks

- Disconnect Terminal Blocks

- Fused Terminal Blocks for Circuit Protection

- Ground Terminal Blocks

W-Series Screw Clamp Terminal Blocks

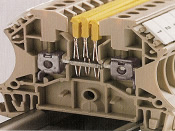

The W-Series Screw Clamp Terminal Blocks were introduced to provide a larger number of varying types of terminal blocks with the same terminal block profile. Not only does this make a more aesthetically pleasing installation but it reduces wiring and maintenance labor costs. It is easier to put the wire into the terminal block when they are all in alignment. Additionally, recent developments in the manufacturing process have enabled the use of the ZQV pluggable jumpers. This allows the option of installing up to 3 rows of pluggable jumpers in the top of the terminal block. These jumpers are easy to install and remain solidly in place as a result of the spring mechanism of the jumper. Jumpers installed in this way do not compete for space with the wiring installed in the cage clamp.

Z-Series Tension Clamp Terminal Blocks

The Z-Series Tension Clamp Terminal Blocks were introduced to provide a solution to vibration-intensive application requirements. Unlike screw/cage clamp design, the Z-Series Tension Clamp Terminal Block Series uses a spring steel mechanism to maintain the conductor in contact with the copper current bar.

This series features a larger marking area, multiple termination points per block, a wide variety of jumpering options, and easy, top-access termination.

SAK Series Screw Clamp Terminal Blocks

The SAK Series modular terminal block was one of the first of its kind to be introduced into the industrial market. The maintenance free, vibration –resistant screw clamp guarantees good contact force and a stable, secure connection. Hardened steel is used for strength in the clamping yoke, while tin plated copper insures superior conductivity through the current bar.

A Wide Range of Products is Available in the SAK Series |

|

W-Series Terminal Blocks With ZQV Pluggable Jumpers |

Z-Series Terminal Blocks With ZQV Pluggable Jumpers |

SAK Series Feed-Thru Terminal Block |

|

| |

|